Partners, not just suppliers

Molds for plastic materials – SMP Stampi Materie Plastiche was created from the insight of Lucia Martinelli and Paolo Santi Amantini, who, in 2002, conscious of their previous professional experience, decided to establish their own company and share their technical know-how. Their aim was to offer to the market of companies producing plastic components (national and international) a threefold service: moulding projects with innovative technical solutions that require a strong technological component; the production of injection molds for plastic and thermoplastic materials entrusted to precision machinery; and the quality and care of craftsmanship for industrial production. Our services are completely tailored to the individual needs of our clients.

SMP Stampi Materie Plastiche is the drive of two generations of entrepreneurs who grew up with the same business vision and dedication to work – proven by their ability to obtain ISO 9001:2015 certification – and who clearly demonstrate their desire to constantly update their personal and corporate development. All this is accomplished in full respect for the environment by making green and eco-sustainable choices both in the use and recycling of raw materials, as well as in the type of production machinery used.

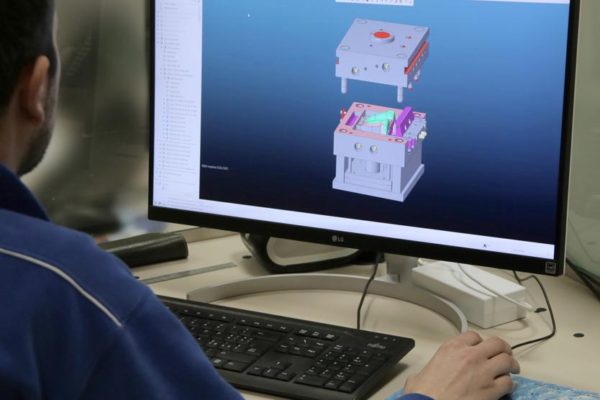

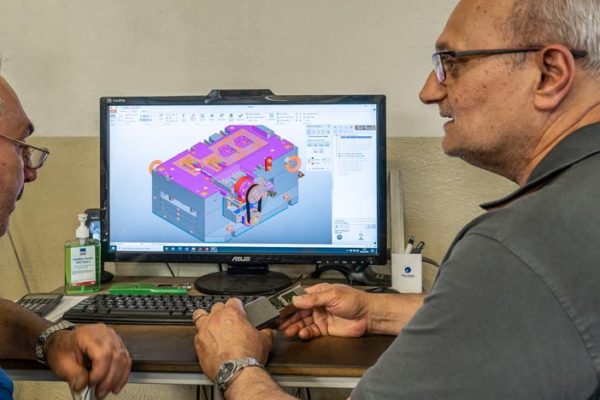

We are committed to the Industry 4.0 Project to transform and digitalise production by integrating new production technologies into our company to improve working conditions and create new business models and production quality that we can offer to our clients. We are always evaluating new possibilities to reach wider market shares and work with new clients on new projects which push us to acquire new skills. All this contributes to the broadening of our technical knowledge and increases our competitiveness on the market.

Our strenghts

Quality Certification

SMP Stampi Materie Plastiche, in line with its internal policy, is an ISO 9001:2015 certified company. Our quality protocol starts from the design office which evaluates the client’s request and carries out a pre-design phase that includes a mould feasibility analysis with related delivery times, and the highlighting of any critical issues together with the possible solutions to these.

Our business protocols allow us to have a precise and coherent methodology; inspections are scrupulous right from the arrival of the raw materials, which are always accompanied by a batch certificate that guarantees their technical, mechanical, and aesthetic compliance. In each production cycle we are committed to guaranteeing our professionalism and a certified quality standard. At the end of each single process, two-fold control checks are carried out. The pre-assembly and final assembly phases of the mould include the inspection of the components using the appropriate Quality control form and the completion of the internal inspection report. A further test verifies the suitability of the mould processing phases and is carried out by an operator on the client’s premises with a specific production machine (press) for thermoplastic materials. The Quality procedure also includes post-sales support for the client.

The main objective of the company Quality Manager is to achieve the maximum satisfaction of the Client. Coherent with this philosophy, our company has obtained its Quality Certification UNI EN ISO 9001:2015, which has been re-confirmed during subsequent verifications.