Mold Pre-design and co-design

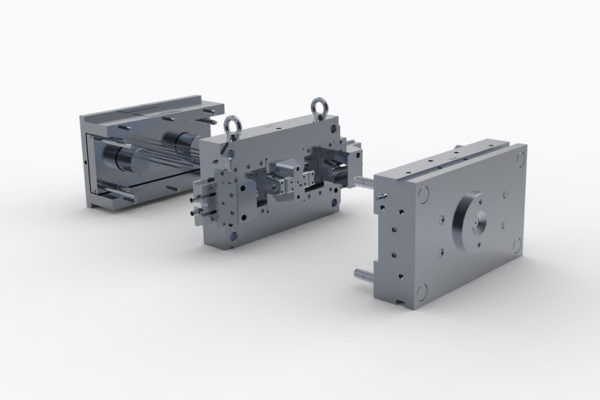

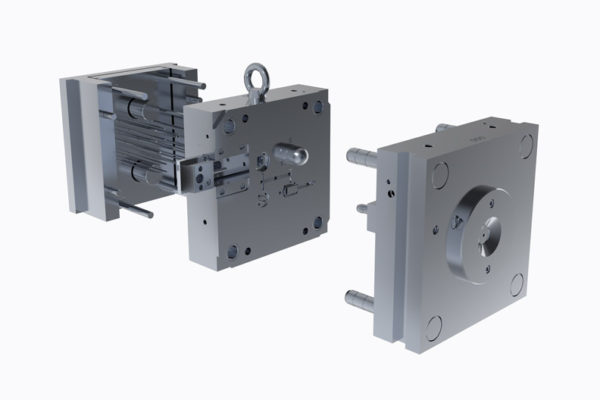

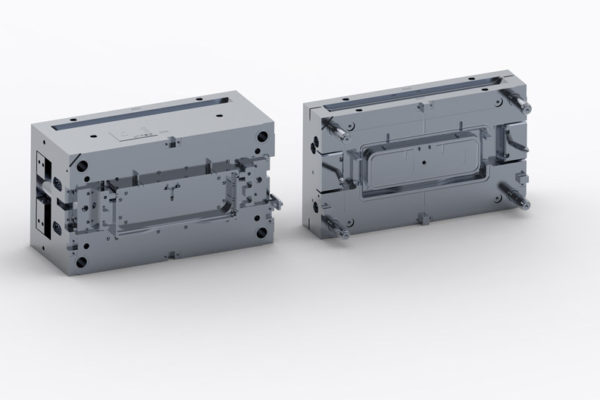

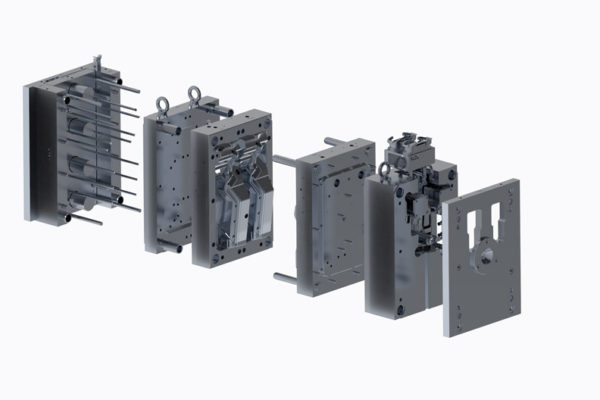

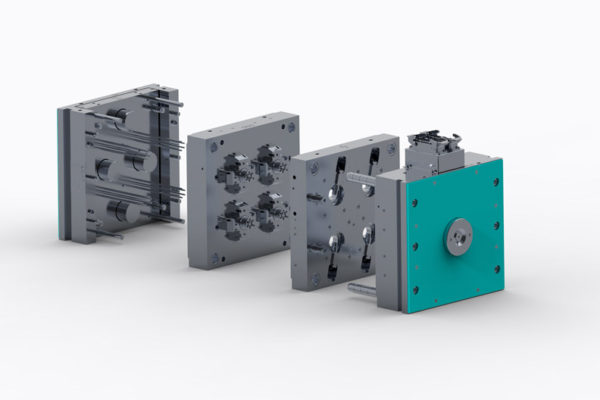

Mold design for plastic materials – The core and the heart of SMP SRL – Stampi Materie Plastiche lies in its technical design office (ufficio tecnico).

To design, according to the way we work, means to analyse, evaluate, and imagine a component in its final use. In order to achieve excellent results, before designing moulds for plastic materials, our expert staff carries out an evaluation of the feasibility of the product in our “pre-design” stage. In the next phase, we work closely with the client using the “co-design” method to fully understand all requests, the intended use of the product, any regulations governing its diffusion, and the technical details necessary for its creation.

Once the feasibility of the project has been verified and perfected, we proceed with virtual simulation using sophisticated CAD/3D software. The CAD modelling software we use is PTC Creo Parametric, latest version. Thanks to these computerised techniques we are able to create three-dimensional objects starting from 2D vector drawings or samples, which help us to carefully observe each tiny detail and to make necessary changes before starting production of the mould. Upon request by the client, we can carry out the prototyping of the component, and the next phase is particularly important because it allows us to touch the quality of the finished product. We therefore create the prototype to be able to test it in detail, that way we can highlight any inaccuracies and correct them before proceeding to the production of the mould.

This is why mold design for plastic materials and the prototyping work carried out by our technical office is essential in order to achieve, through continuous improvement, the optimal result of the project.