Benefits of injection molding

The benefits of injection molding are:

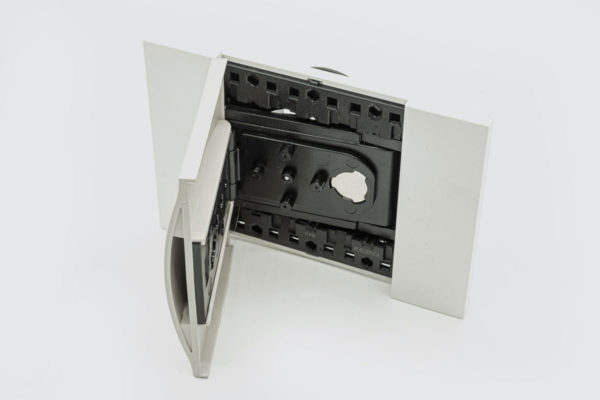

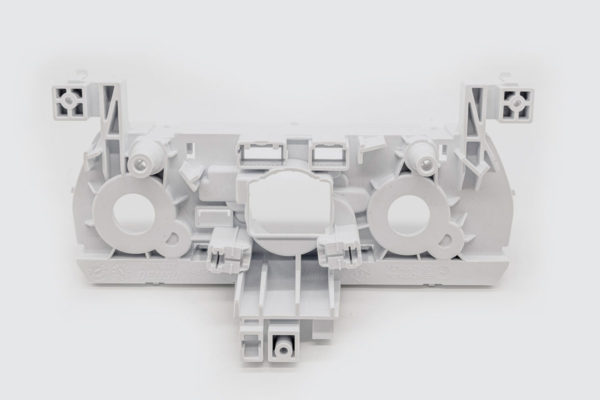

• The possibility to produce pieces with complex geometries.

• The high productivity and competitivity combined with the automation of the moulding process.

• Low production costs, which compensate within a short time the investment in a mould.

• The possibility to product components of variable shape, size, and weight, from a few grams to many kilograms.

• The possibility to produce components in a constant and uniform way.

• The possibility to produce components coupled with metal or electronic inserts in the moulding production cycle.

• The possibility to create a multicavity injection mould or a family injection mould.

• The possibility to modify and reuse the injection mould.

• The possibility to remove unnecessary details and get rid of undercuts.

(Alternatively, it is possible to create movements which create complex undercuts and structures.)

Injection molding of thermoplastic materials is the most diffused technology in the transformation of plastic materials.

• Mould for thermoplastic materials with central core injection.

• Mould for thermoplastic materials with runner injection – tunnel.

• Mould for thermoplastic materials with runner injection – fan.

• Mould for thermoplastic materials with free flow hot nozzle injection

• Mould for thermoplastic materials with hot nozzle filling injection.

• Mould for thermoplastic materials with hot runner injection.

• Injection mould for thermoplastic materials with mechanical movements.

• Injection mould for thermoplastic materials with oil-hydraulic/pneumatic movements.

• Injection mould for thermoplastic materials with nitride or hardened movements.